The Macromolecule alloy cable tray, which was researched and developed by Changhong Plastics Group Imperial Plastics Co., Ltd, introduce of the industry concept and the technology in Orlando, USA. It was produced according to American UL568 standard processing, and passed the National Fire Protection Building Materials Quality Supervision and Inspection and China Quality Certification Center CQC safety test. The product has advantage of insulation, corrosion-resistant, anti-aging, light weight and long service life. The company can produce according to customized demand for a variety of special products and recyclable recycling. The products have properties of environment protection, energy-saving and convenient to use. The products are widely used in the United States, France and Southeast Asian countries. It is the first new kind in our country, is a model of a new generation of scientific and technological innovation.

Macromolecule alloy cable tray is a new paragon of replacing steel with plastics after PVC fire-resistant cable trough in Electrical application engineer field. It has good physical properties and chemical properties, also possess the good features of PVC like fire-resistant, acid-resistant, alkali-resistant. Based on UL568 standard, it is made from a special high molecular material and mixed with functional additives containing other features. It's widely used in Europe and America, and developed countries and regions in Southeast Asia for its energy conservation and environment protection nature.

For its outstanding features and low cost, macromolecule alloy cable tray is approved and applied in different fields and industry. In developed countries and regions, it commonly used in the field of subway, mining, metallurgy, communication, oil, chemical engineering, coal, textiles, electricity, mechanical, transportation, shipping, water treatment, paper-making, civil building, industrial workshop, new energy PV and wind power project, etc.

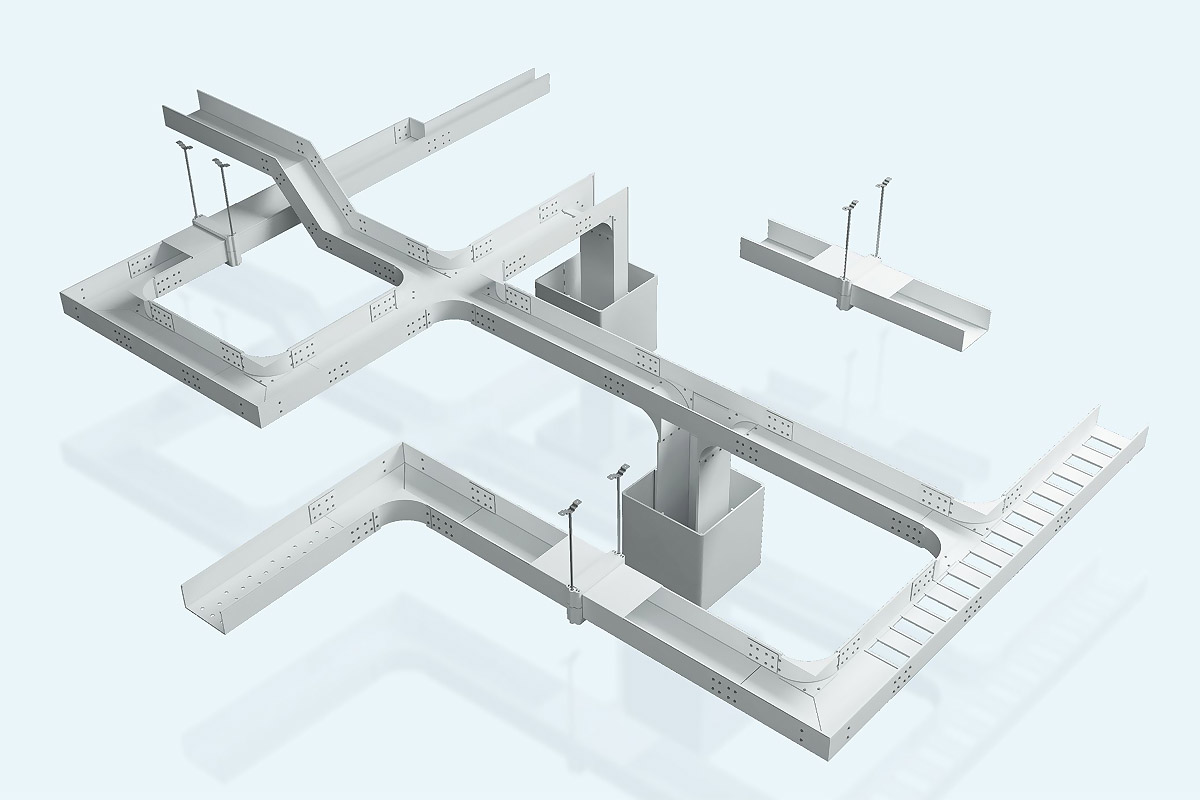

The channel-type of Macromolecule alloy cable tray is fully closed model. It is suit for lay of computer, telecommunication cable, power cable etc. and specially suit for protecting cables in heavy corrosion environment. Ladder type and tray type cable tray is made based on improved foreign-related technology, it has light weight, heavy duty, unique shape and other characteristics.

Macromolecule alloy cable tray is designed to suit different application scenario, which is accord with the advocated policy of Replacing steel with plastics, Energy-saving and cost-reducing, Environmental protecting. Under innovative and advanced design concept, Macromolecule alloy cable tray will be the priority choice in constructional engineering in near feature and have bright market prospect.

Innovative Concept

With global climate change continues, environmental consciousness constantly enhanced among citizen; with rapid development of economy and modernization construction of our country, the national strategy turns to favor of Low-carbon and cyclic economy, which will push the traditional energy dissipation product to be improved and replace.

Therefore, after done sufficient research, we developed Macromolecule alloy cable tray and put into production. The manufacture process is first mix PVC, ABS, PS etc. unsaturated polyester resin and variety of polymer and high molecular resin with flame retardant chemical additives, then plasticizing the material, finally extrusion molding or injection molding, shaping and cutting. Its physical and mechanical features are better than metal cable tray. It will be the priority choice to replace metal cable tray in 21th century.

For its special design, macromolecule alloy cable tray is decorative and flexible. The installation is much less complicated than steel cable tray installation and need less fittings which will greatly improve efficiency and reduce cost.

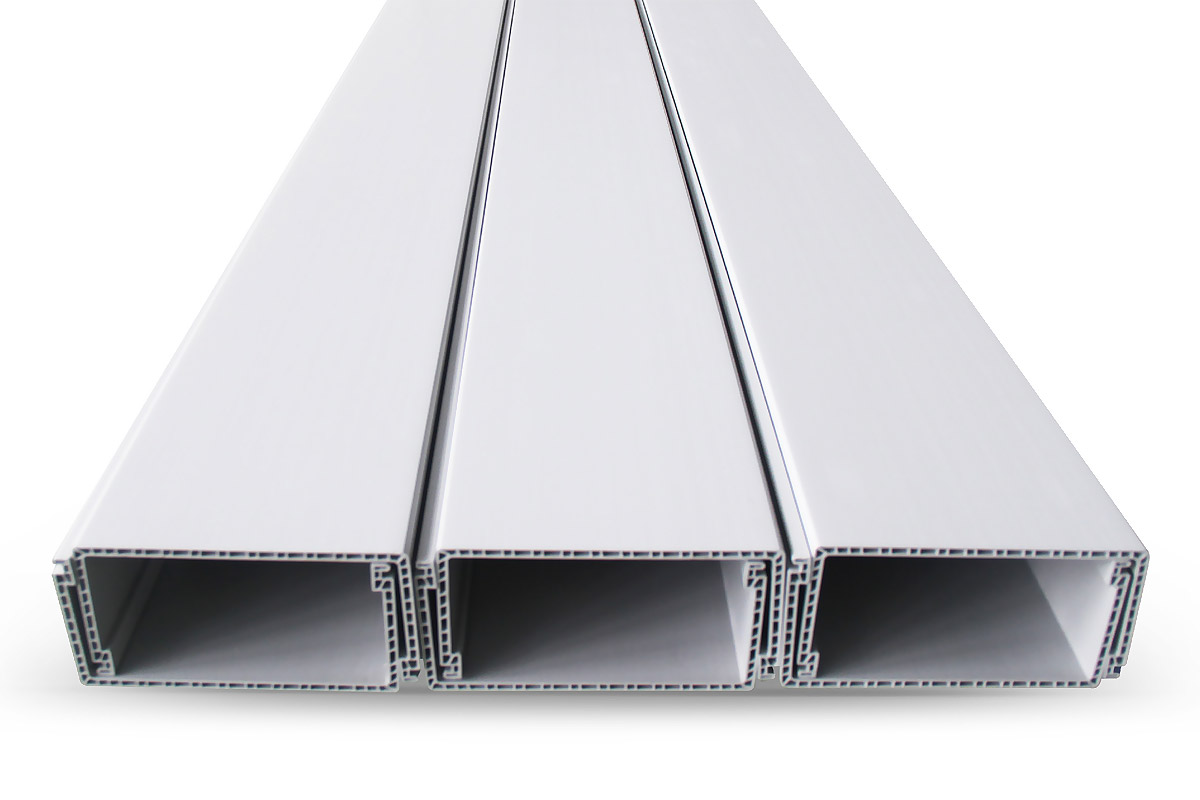

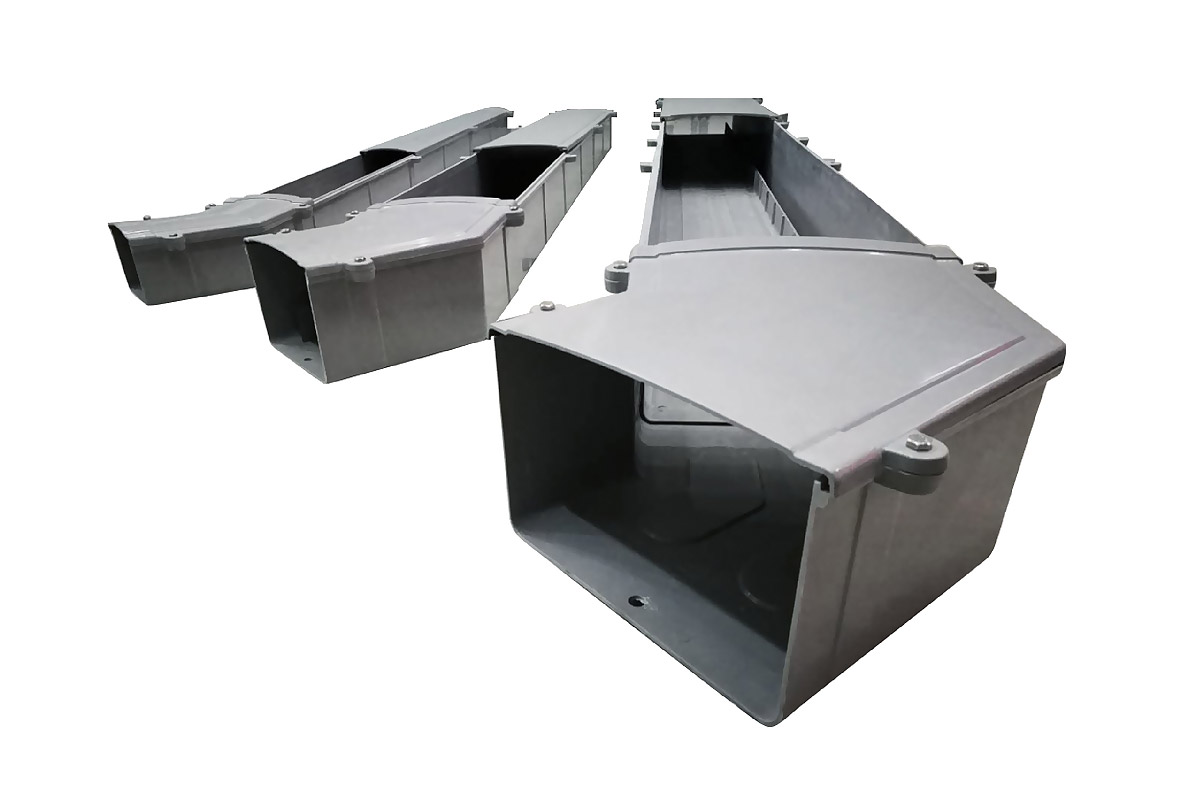

Macromolecule ally cable tray has slot type, bore type and ladder type. It is combined by two part: baseboard and cover. The U groove of the bottom plate is a part of the cable. The double hollow structure is extruded continuously by the extruder. It not only has super strong mechanical structure, but also greatly reduces the weight of the product. Cover can be monolayer or double-layer. There is snap joint on baseboard and cover to connect each other. This design is easy to close and open, convenient for installation and maintenance, repair and technical reforming.

Application Fields

For its exclusive features of good insulating, corrosion resistance, high oxygen index, and long service life, etc, macromolecule alloy cable tray is approved and applied in different fields and industry, such as civil building, subway, mining, port, oil, chemical engineering, coal, textiles, electricity, mechanical, transportation, shipping, water treatment, pharmaceutical factory, paper-making, civil building, industrial workshop, new energy PV and wind power project, etc.

● Railway

The railway belongs to the area of traffic flow, and the demand for the products is high. This product either on the ground or underground environment, has moisture-proof, anti-corrosion, rust, dust and other characteristics, and through the product structure, the automatic formation characteristics of air flow adjusting temperature and water vapor from inside and outside, have important measures to protect the safety of the product.

● Petrochemical Engineering

Petrochemical engineering is usually carried out in outdoor and extremely hostile environment perennially. The climate changing requires products to be high temperature resistance, low temperature resistant, aging resistance under strong UV light, anti-static and strong durability. Macromolecule ally cable tray has as UV-resistant, antioxidant and anti-static additives mixed in the material to enhance durability and safety.

● Civil building

Civil buildings can be divided into two categories: residential buildings and public buildings according to the function of use. The civil buildings in the People's Republic of China people's Air Defense Act refer to houses, hotels, guest houses, shops, teaching buildings and offices, scientific research and medical rooms. The "civil architecture" is different from "military buildings" and productive industrial buildings.

● Power industry

In 2015 the national Power Grid Corp operating area of society as a whole amount of 43721 kwh, the country is expected to power installed capacity of 1 billion 960 million KW, 2030 to 2020 demand demand 3 billion 20 million KW and 3 billion 980 million KW demand in 2050, the thermal power installed capacity accounted for decreased year by year, 2020, 2030 and 2050, the installed capacity accounted for 61%, 51% and 38%. With the deepening of the national electric power system reform and the continuous heating in the new energy field, the demand for new products is gradually increased by users. This product basically covers all areas of the middle and lower reaches of the electric power industry chain, and will be the first choice for the future power industry.

● Utility Tunnel

Guiding opinions of the general office of the State Council on promoting the construction of city underground pipe gallery (Guo Ban Fa 2015 No. 61) announced on August 10, 2015. The goal of our work is to build a batch of 2020, with the international advanced level of underground pipe gallery and put into operation, repeatedly digging the ground "road zipper" problem is obviously improved, significantly enhance the pipeline safety level and disaster prevention and mitigation, the gradual elimination of the main street spider net type overhead line, city landscape significantly improved. This product is superior in corrosion resistance.

Macromolecule ally cable tray itself is insulated, anti-corrosion, flame-retardant and weather resistant, but added with functional additives, it can obtain different features. It contains the good features of hot dip galvanized cable tray, aluminum alloy cable tray, FRP cable tray, etc, also macromolecule ally cable tray is recyclable and energy conservation and environment protection.

Description

1) Green environmental protection, energy saving and consumption reduction

a) production process is simple, the installation process does not need to open the welding equipment, such as welding, the use of environmentally friendly materials to reduce industrial pollution sources and no impact on the environment.

b) products can be recycled after processing and recycling, environmental protection requirements, to achieve recycling economy.

c) polymer alloy cable tray production completed in one of the automatic production line, the complex process of multi-channel saving than the traditional metal cable tray.

d) due to the small proportion of raw materials, only 1/5 of steel, in the process of loading and unloading, transportation, construction and installation of a large number of labor costs and energy savings.

2) "Double hollow structure design" concept

According to the mechanical structure and thermodynamic principle, combined with the demand of traditional products, polymer alloy cable tray adopts a double-layer hollow structure, improve product capacity in reducing product weight at the same time, to prevent the stress due to the integral structure of bridge caused warping deformation, the impact resistance, toughness, strength and other performance is more superior to the metal products, cable protection skin, prevent heat accumulation caused leakage, soluble epidermal adhesion.

3)“Double Lock”

Polymer alloy cable tray by U type slot box and the cover plate is composed of two parts, on both sides of the cover plate buckle feet inward, the installation process, the buckle foot coincided with U groove on both sides of the box abduction is buckled, truly seamless. When opened, applied only slightly in the joint force, the bridge itself with toughness and flexibility, can cover. This "double locking type" structure, easy to install, save manpower and material resources, shorten the installation period, but also for the future system expansion, technological renovation, maintenance convenience.

4) High fire retardant

The cable tray is made of high quality polymer alloy composite material. According to the national fire product quality watchdog, the national fire protection building materials quality supervision and inspection center according to the GB 20286-2006 "public places of flame retardant products and components, combustion performance requirements and marking," GB 8624-2012 "of building materials and products" standard for the flammability classification of testing products, the oxygen index of 58.1%, reached the performance of B1-b grade (national standard combustion flame retardant). The product does not delay the ignition and from the fire.

5) Low smoke and low halogen

Polymer alloy cable tray using a special formula and process of product innovation, low smoke and low halogen, toxicity index test, reach T0 level. After the combustion test of 600s, no burning drip. even in the event of an accident, fire, flame retardant polymer alloy cable tray can be well spread to protect the user property and control the maximum degree of safety.

6) Insulation, no current vortex

Polymer alloy cable tray due to the insulation material with high quality, reliable insulation performance. The product does not conduct electricity, does not need the ground, causes it to have the remarkable performance in the security. Cable tray laying in transformer does not produce magnetic field effect, not the formation of current vortex, avoid the cable due to current vortex generated by the heat, save the current loss caused by overheating.

7) Corrosion resistance, aging resistance, long life, maintenance free

The raw materials of polymer alloy cable tray has natural antiseptic antioxidant efficacy, combined with different functional additives, the product has the characteristics of no rust, corrosion resistance, acid and alkali resistance, the product surface does not need anti-corrosion treatment, technological innovation, strong weatherability, no need of maintenance in the application, the product has anti-aging quality better that is suitable for different climate and other special corrosive environment, the service life can reach more than 36 years.

8) Easy installation, no need to connect

Polymer alloy cable tray through optimizing the structure design, the bridge between the section without the use of to ensure the bridge through the soft connection. In order to meet the stress conditions, the bridge can be cut according to the actual situation, through bolts and nuts and accessories can be assembled freely, convenient and quick, shorten the installation period, improve work efficiency.

9) Beautiful appearance, strong practicality

Due to production and processing in the application of the mold pultrusion process, the polymer alloy cable tray, neat appearance, smooth lines. The color of the raw material can be modulated according to the different needs of the customers before the granulation, and the product has the advantages of uniform color, beautiful appearance and strong decorative effect.

中文简体

中文简体 English

English ภาษาไทย

ภาษาไทย 日本語

日本語

Inquiry

Inquiry

Shrink all details

Shrink all details